Projectmanagement

From product planning to the production process to the finished product, we are strong partners in value creation for our customers. With high demands on our performance, we find the most efficient solution.

Supply chain management

By integrating all necessary suppliers and partners, we ensure your complete supply chain. From planning and procurement to production and delivery, we ensure that all processes run reliably and smoothly. We always make sure that your supply chain is efficient and cost-effective. To achieve this, we rely on state-of-the-art technologies and close cooperation with our partners.

Development and co-design

Our engineers are industry experts and offer close transparent cooperation. They support the development and design of your components right from the start. Together with you, we develop customised solutions that efficiently realise your products.

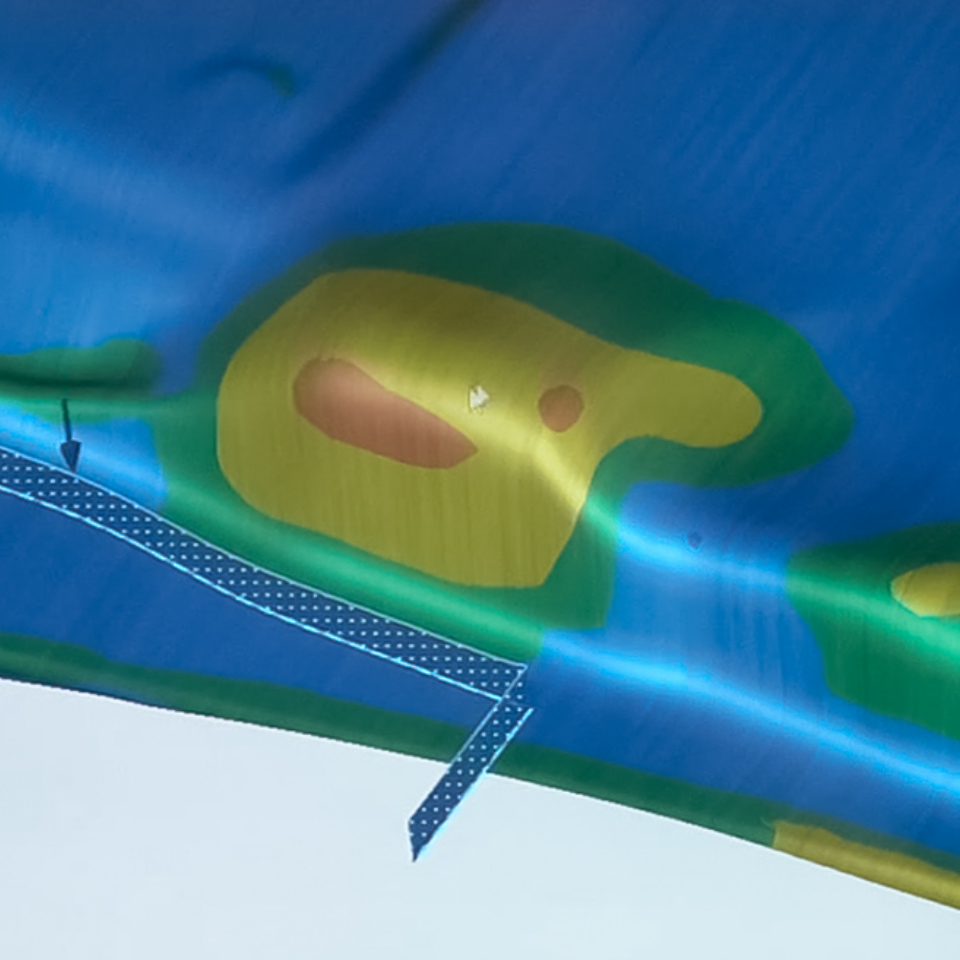

Forming simulation

Through forming simulations, we identify potential challenges and problems at an early stage and can rectify them. In this way, we ensure that the developed parts meet the desired requirements.

Process optimization

We offer professional process development that works out stable and repeatable manufacturing processes while adhering to our standards for reliable component quality. Our experienced experts analyse existing processes and identify potential for optimisation. In doing so, we take individual requirements and needs into account.

Tool management

We offer holistic tool management that covers all aspects – from planning the tooling methods and ensuring them through forming simulation to detailed design and control as well as maintenance of the fixture and tooling construction. This enables us to ensure high availability and a long service life of the tools.

Our workflow

01Communication

Through open communication with our customer, we ensure that we fully understand their needs and expectations. Through close collaboration and regular updates, we see if we are on the right track and make adjustments where necessary to ensure customer satisfaction.

02Product planning

Product planning is a crucial step in ensuring that customer requirements are met. By thoroughly analysing the requirements in close cooperation with our customers, we can understand their needs and translate them into efficient solutions. It is important to keep in mind both their functional requirements and their expectations in terms of quality, reliability and cost.

03Production process

In the production process, the focus is on efficiency to ensure optimal use of resources. This includes selecting the right production methods, using modern technologies and continuously improving processes. By optimising processes and reducing waste, we can increase efficiency while controlling costs.

04Quality controls

At the end of the process, we deliver a finished product that meets our customers’ high standards. This requires quality controls to ensure that all specifications are met – and careful packaging and delivery to hand over the product in perfect condition.

05Customer retention

We want to convince our customers in the long term and establish lasting partnerships. That is why we place extreme importance on excellent customer service, fast response times, effective problem solving and added value for our customers.

Contact

We look forward to receiving your enquiry! Please describe your requirements in the contact form.

Münchener Str. 45

85123 Karlskron-Brautlach